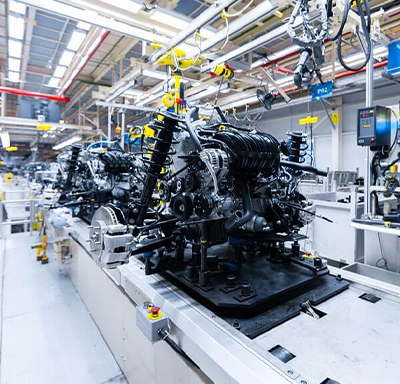

Material Handling

Robotic material handling and tending systems are commonplace in the industrial sector.

Dispensing

The technologies in MultiFlo FX microplate dispenser enable many liquid handling applications from 2D and 3D cell culture to concentration normalization assays, ELISA, bead-based assays and more.

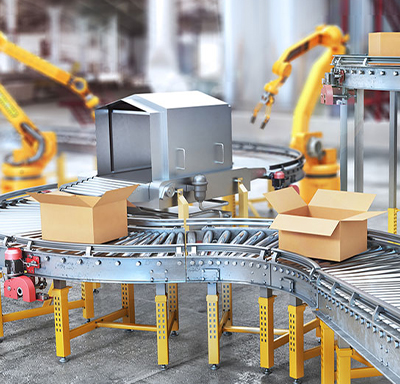

Palletizing

Palletizing is a demanding application of stacking boxes, bags, cases, bottles, and cartons onto pallets as the last step in the assembly line before being loaded onto a shipping truck.

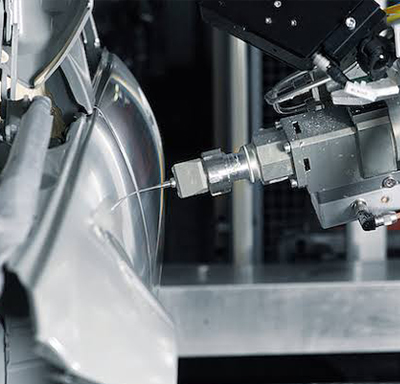

Welding

Robotic welding is a highly advanced version of automated welding, in which machines conduct the welding, but welders still control and supervise the process.

Deburring

Deburring is the process of removing burrs, edges, inconsistencies or fins off of parts. Robotic deburring is when this process is carried out by industrial robotic arms.

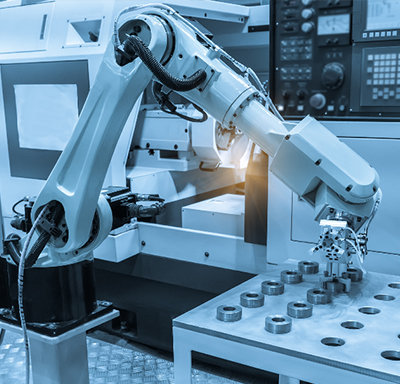

Machine Tending

Robotic machine tending (CNC Machine Automation) is the process of using a robot system to automatically load and unload a production machine.

Milling

Robotic milling is the process of cutting material away from a prototype or mold to form a specific structure.

Grinding

Robotic grinding and robotic material removal processes have been adopted by manufacturers around the world because of the many productivity benefits they provide.

Polishing

Robot polishing is a great way to improve safety, quality, and consistency of polished products. Both big and p businesses can use robots to improve their polishing tasks.